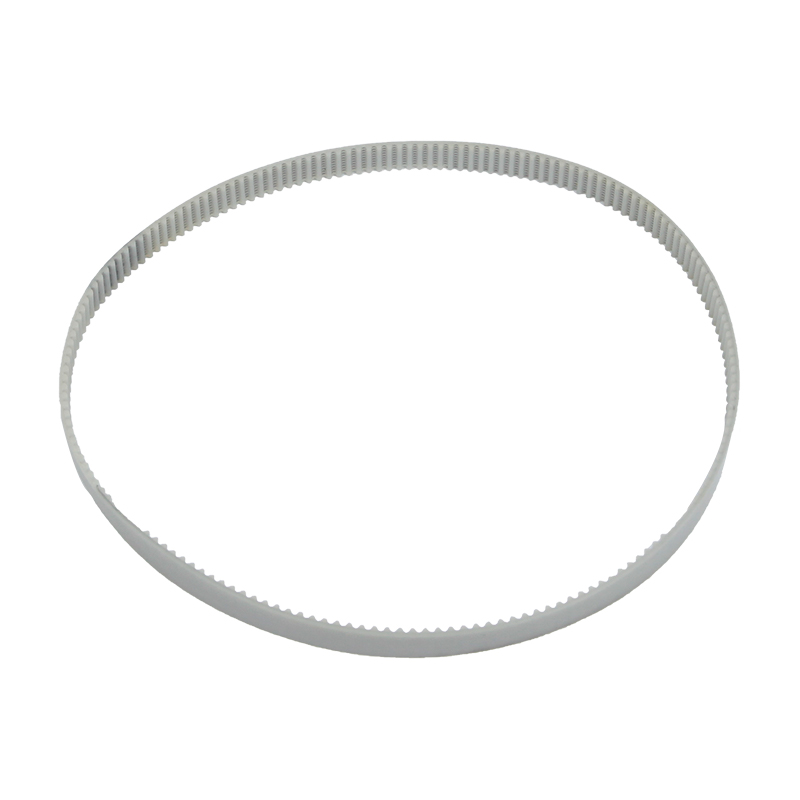

Polyurethane timing belt, also known as polyurethane timing belt, is also a very common material, most of which are composed of polyurethane elastomer and high-strength steel wire. Materials such as polyurethane elastomers have high wear resistance, and the various wire cores inside can ensure stable operation during their rotation. The open polyurethane synchronous belt has stable transmission and stable specifications. In the production process of the factory, adding a layer of nylon cloth on the tooth surface or back can ensure that the characteristics of the actual operation will not change in special applications. A thick layer of polyurethane can be added to the back of the drive belt, which can well avoid the problems of high corrosion or high load.

Polyurethane timing belt: Polyurethane timing belt is usually made of nylon wire (or steel wire, copper wire) as a tensile body, and polyester fiber is poured, which has the characteristics of aging resistance, impact resistance and good appearance.

Rubber timing belt: The rubber timing belt has good flexibility and wear resistance, but polyurethane is not resistant to moisture, has poor repeated operation performance, and has poor high and low temperature test characteristics. Polyurethane synchronous belt is good in constant temperature and static environment. Otherwise, rubber synchronous belt is good.

English

English 中文简体

中文简体 عربى

عربى