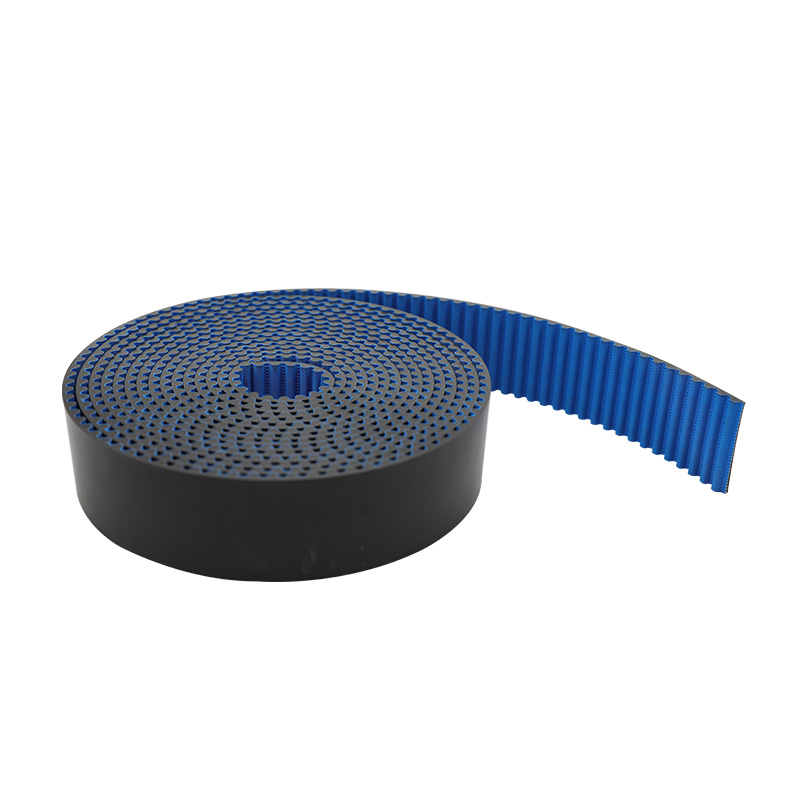

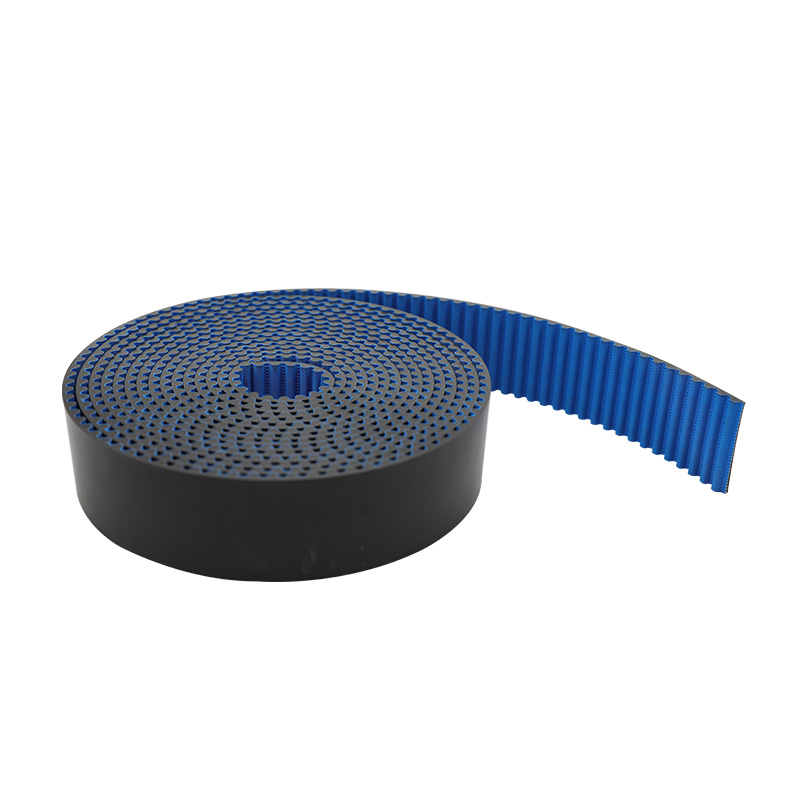

The timing belt drive is composed of an endless belt with equidistant teeth on the inner peripheral surface and a pulley with corresponding teeth. During operation, the belt teeth mesh with the tooth grooves of the pulley to transmit motion and power. It is a comprehensive belt. A new type of belt drive with respective advantages of transmission and chain drive gear transmission.

Precautions for installation and use of timing belt and synchronous pulleys:

Reduce the center distance of the pulley. If there is a tensioner, loosen it first, and then adjust the center distance after installing the belt. For the transmission with fixed center distance, the pulley should be removed first, the belt should be installed on the pulley, and then the pulley should be fixed on the shaft.

The following points should also be noted when installing:

①When installing the timing belt, if the center distance of the two pulleys can be moved, the center distance of the pulleys must be shortened first, and then the center distance should be reset after the timing belt is installed. If there is a tensioner, first loosen the tensioner, then install the timing belt, and then install the tensioner.

②When installing the timing belt on the pulley, remember not to use too much force, or use a screwdriver to pry the timing belt, so as to prevent the tensile layer in the timing belt from being broken. When designing the pulley, it is better to choose a structure in which the two shafts can move closer to each other. If the structure does not allow it, it is better to install the timing belt and the pulley on the corresponding shaft together.

③ Control the appropriate initial tension.

④In the timing belt drive, the parallelism of the two pulley axes is required to be relatively high, otherwise the timing belt will deviate during operation, or even jump out of the pulley. Non-parallel axes will also cause uneven pressure and early wear of the belt teeth.

⑤ The frame supporting the pulley must have sufficient rigidity, otherwise the pulley will cause the two axes to be non-parallel when the combination lock is running.

English

English 中文简体

中文简体 عربى

عربى