This type of belt is available in a number of different shapes and sizes. It is important to choose a belt that will perform well in the environment it is being used for. This is a very important step when choosing a timing belt.

The type of material that is used in a timing belt is also very important. Each material has different properties that make it the best choice for a specific application.

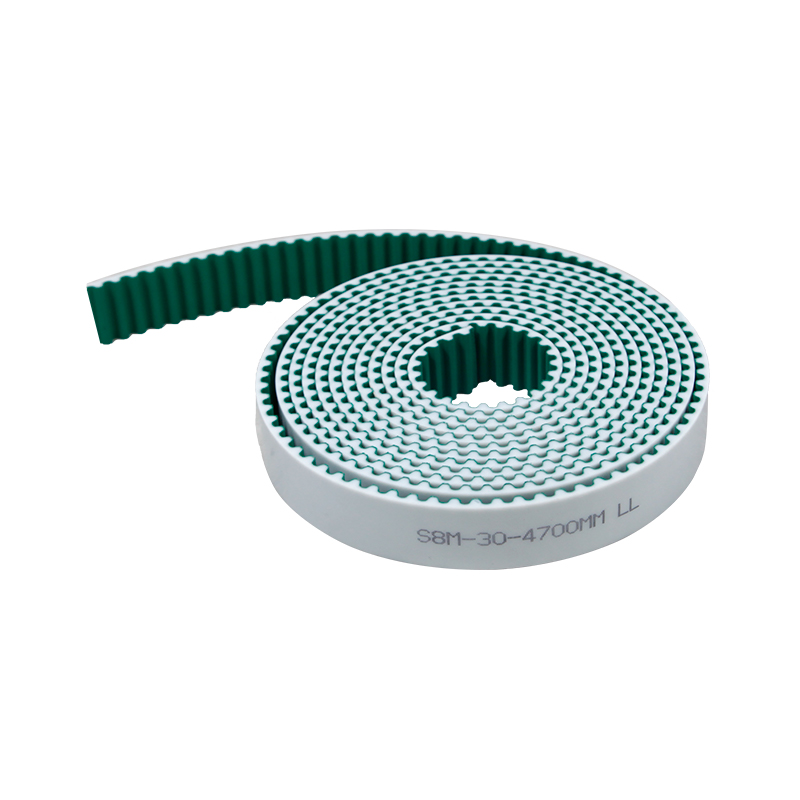

PU open timing belt is a strong and durable belt that can withstand a variety of environments and conditions. It can be molded with different colors and designs to match your application.

It is also possible to add a fabric covering to the teeth of this type of belt in order to reduce friction and noise. This type of belt is also a great choice for applications that need to be very precise.

These types of belts are a great choice for small drives and high-precision positioning and sorting machines. They can handle loads of up to 100 kg and are very strong.

Spliced and welded timing belts are also a great option for general-purpose applications. They have the same sealed edges and smooth back as an open-ended belt, but they also have a 50% increase in break strength because they are welded.

English

English 中文简体

中文简体 عربى

عربى