Polyurethane timing belts are manufactured using state-of-the-art processes. They are abrasion-resistant, long-lasting, and durable. They are ideal for applications that require ozone resistance, high temperature resistance, and high resistance to water and oil. They are also suitable for quiet running. They can also be reinforced with different fibers.

Polyurethane molded timing belts are made in special molds. The molding process is a unique thermoset molding process. They are manufactured to tight tolerances. This ensures consistent width, pitch length, and thickness.

Polyurethane molded timing Belts are available in several shapes and profiles. They are available in standard and custom lengths. They are manufactured with high pitch accuracy. They are ideal for linear and roller drive systems. They are also used in food processing applications. They are resistant to oils, ozone, and concentrated acids. Polyurethane molded timing belts have a pinhole location.

Polyurethane timing belts have a high tensile strength and are available in different tensile strengths. They are designed to accommodate a wide variety of loads. They are available with high-strength steel cords. They are also available with aramid cords. These fibers offer a high tensile strength and small elongation.

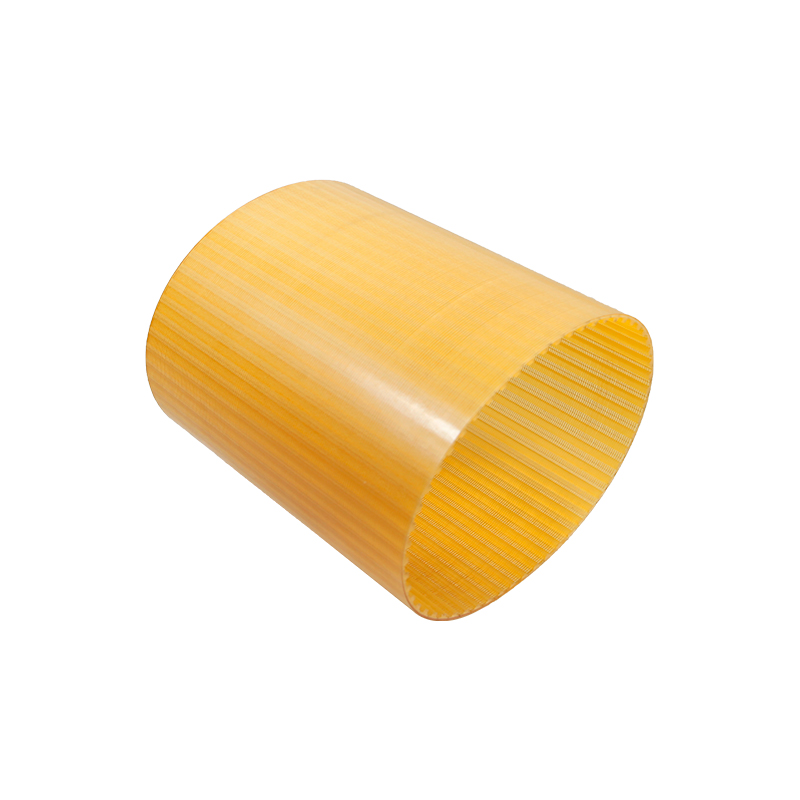

Polyurethane molded timing sleeves are also available. They are cast in a special mold and have high pitch accuracy. They are ideal for cigarette pressing machines and food processing applications.

English

English 中文简体

中文简体 عربى

عربى