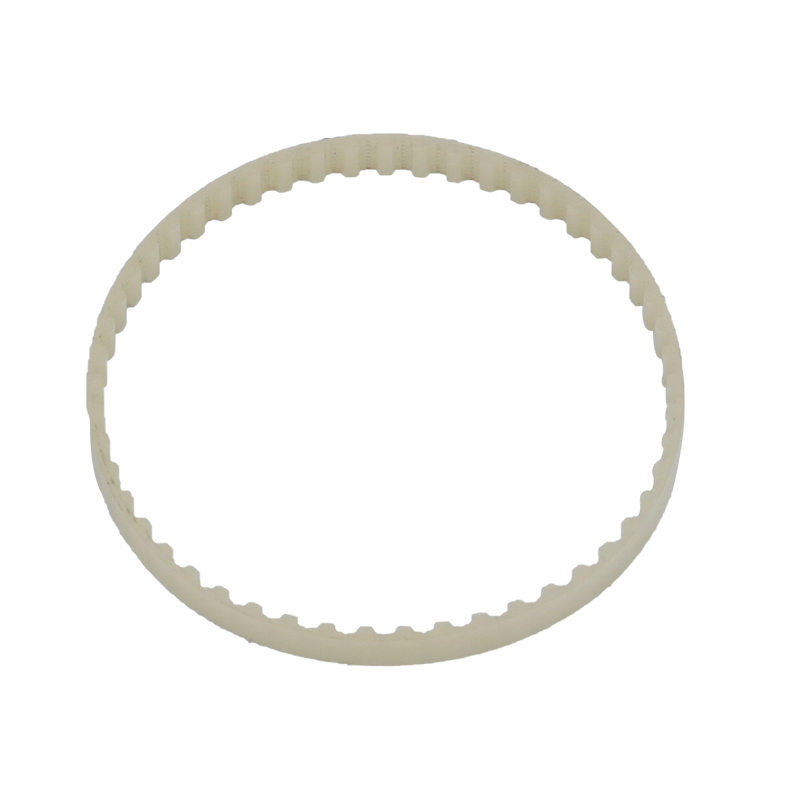

The polyurethane material used in the production of the belts has an extremely high load capacity. It also offers excellent resistance to abrasion, oils and acids. PU timing belts are available in Open, Welded Endless and Flex designs. These high performance belts are used in machine, automotive, agricultural and household industries. They are also ideal for a wide variety of power transmission applications.

These belts are also available in a wide range of widths. Polyurethane timing belts are designed for high shock loads and offer high flexibility, high load capacity and long term reliability.

Polyurethane molded timing belt sleeves are cast in special molds to ensure high pitch accuracy. The nylon fabric used in the sleeve helps to ensure accurate holding of the tooth profile. In addition, the polyurethane jacket provides superior non-crumbling and non-marking performance. This jacket is also used in paper and cigarette press machines.

Polyurethane timing belts have strong fiberglass cords that offer excellent tooth shear strength and high load carrying capacity. This makes them ideal for applications that require high resistance to shock loads.

Polyurethane timing belts also have different tooth forms. These include helically spooled, synchronous and flex belts. Synchronous belts provide excellent mechanical resistance to tooth, while flex belts have spiral coiled tension members.

English

English 中文简体

中文简体 عربى

عربى